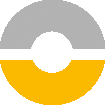

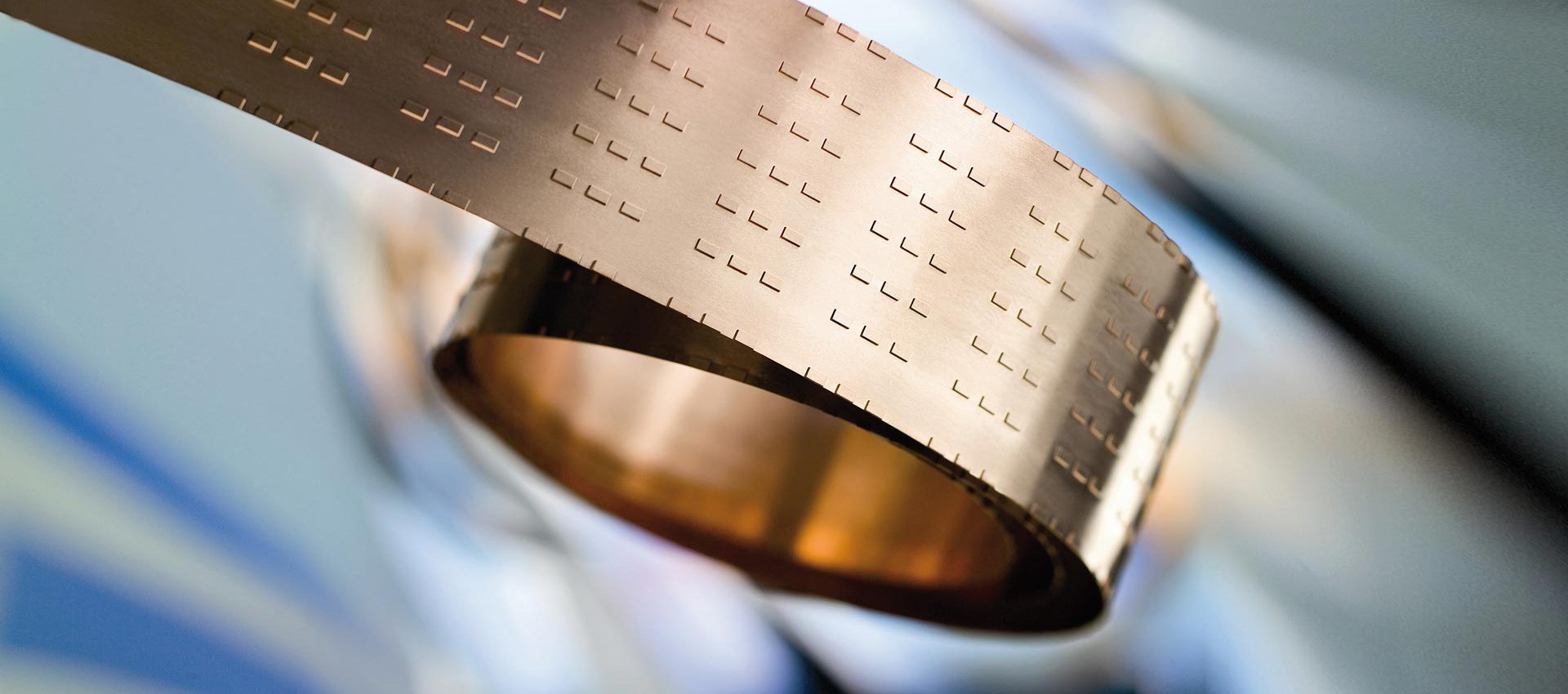

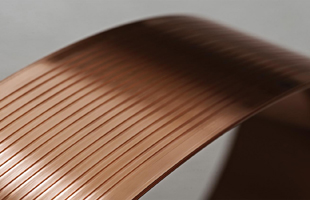

Optimise your punching process through the use of Profiltech strips. Profiltech is your ideal partner for milled semi-finished products for the electronics, power electronics and e-mobility industries.

Whether connectors, relays, contact parts, power LEDs, semiconductor carriers, power modules or cell connectors for battery technology, our profile strips guarantee more productive further processing in stamping technology. The right profile strip for every customer. This philosophy is our principle and will continue to drive the innovations of our company in the future. Find out for yourselves about our innovative milling techniques on our website and contact us.